- #XBAR CHART HOW TO#

- #XBAR CHART MANUAL#

Look for special or assignable causes and adjust the process as necessary to maintain a stable and in control process.įormulas from 2002, Manual on presentation of data and control chart analysis, ASTM International, West Conshohocken, PA.

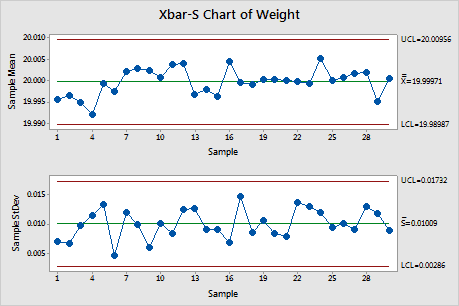

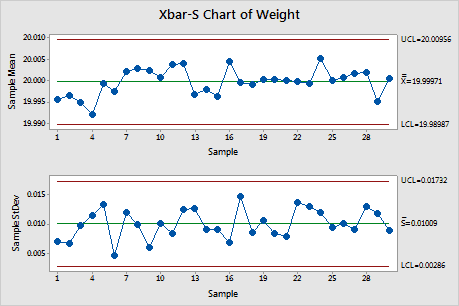

With the control limits in place, gather samples, and plot the data. Once you decide to monitor a process and after you determine using an $- \bar$$ 8.

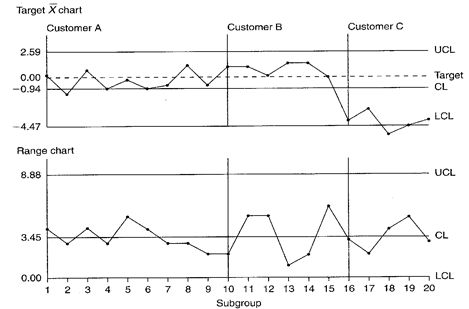

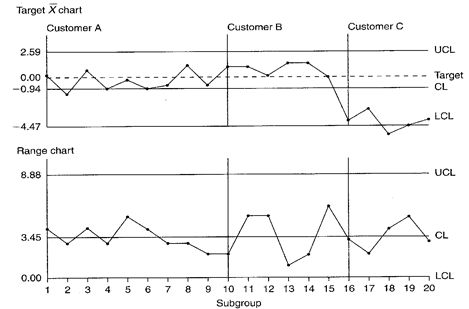

Root Cause Analysis and the 8D Corrective Action Process course. An Introduction to Reliability Engineering. Reliability Analysis Methods online course. 14 Ways to Acquire Reliability Engineering Knowledge Year: 2013 Title: A robust Xbar control chart Journal: Quality and Reliability Engineering International Volume Issue number: 29 7 Pages (from-to). Innovative Thinking in Reliability and Durability. Equipment Risk and Reliability in Downhole Applications. Musings on Reliability and Maintenance Topics. Mostly in automotive industry used widely to determine its process stability and predictions. It may have a drive a subgroup size of two or more to measure standard chart for variables data. Metals Engineering and Product Reliability An XBar and R (range) Chart study is a statistical quality control chart used to monitor variables of product criteria. Product Development and Process Improvement. Rooted in Reliability: The Plant Performance Podcast. The X-Bar Charts indicate that machine 2 is in control, but machines 1 and 3 aren’t. The R-Charts for the three machines indicate that the process variation is in control, no points are out of control, and all points fall within the control limit in a random pattern. The engineer examines the R-Chart first because the control limits on the X-Bar charts are inaccurate if the R-Chart indicates that the process variation is not in control. Three X-Bar, R-Charts are created, one chart for each machine. The quality engineer has to measure five ignition coils from each machine during each shift.Īn X-Bar, R-Chart can be developed for each machine to monitor ignition coil lengths. Three equipment machines manufacture these ignition coils for three shifts per day. Otherwise, there’s no way to identify if the process has changed, or to locate the origins of the process variables.Įxample – How X-Bar and R-Chart Can be UtilizedĪ quality engineer at automotive body parts manufacturing plant may use X-Bar and R-Charts to monitor the lengths of ignition coils. X-Bar and R-Charts can also be used for standardization, which is why data should be collected and analyzed throughout the process operation. This lets a business determine how a process is running and compare it to historical performance to see if process changes produced the right improvement. X-Bar and R-Charts can be applied to analyze process improvement results. Data must be collected and entered in a manner that enables you to stratify by symptom, operator, location, or time. This X bar chart calculator will show you all the steps required to construct an X-bar chart, which is one of the most common charts used to assess whether. Different results may be found between shifts among different workers, or different machines and equipment, or among different materials, for example. Once the stability has been assessed, you must figure out if the data needs to be stratified. These subgroups can then be used to measure system stability. These functions are used to compute statistics required by the xbar chart for one-at-time data. Apart from generating the basic control chart, we will look at how we. First, they would want to collect as many subgroups as possible to accurately calculate control limits. Xbar R charts are often used collectively to plot the process mean (Xbar) and process range (R) over time for continuous data. As with all control charts, the Xbar-R charts are used to monitor process stability. #XBAR CHART HOW TO#

They may want to figure out how to improve their processes and operations by analyzing results through this statistical method. Take a manufacturing plant, for instance. When improving a system, X-Bar and R-Charts have numerous applications that enable system stability to be evaluated.

Applications of X-Bar and R-Chart for System Stability

0 kommentar(er)

0 kommentar(er)